Electrical

The Magna has 4380W of solar, 38kWh@48V, and an 8kW diesel generator to supplement when needed. We carried over several components from our fifth wheel, and generally utilize solar, keeping generator run time as rare as possible. In 2023, we ran the generator around 15 hours, including maintenance runs, which we tended to schedule around when we could use the power to help charge our batteries.

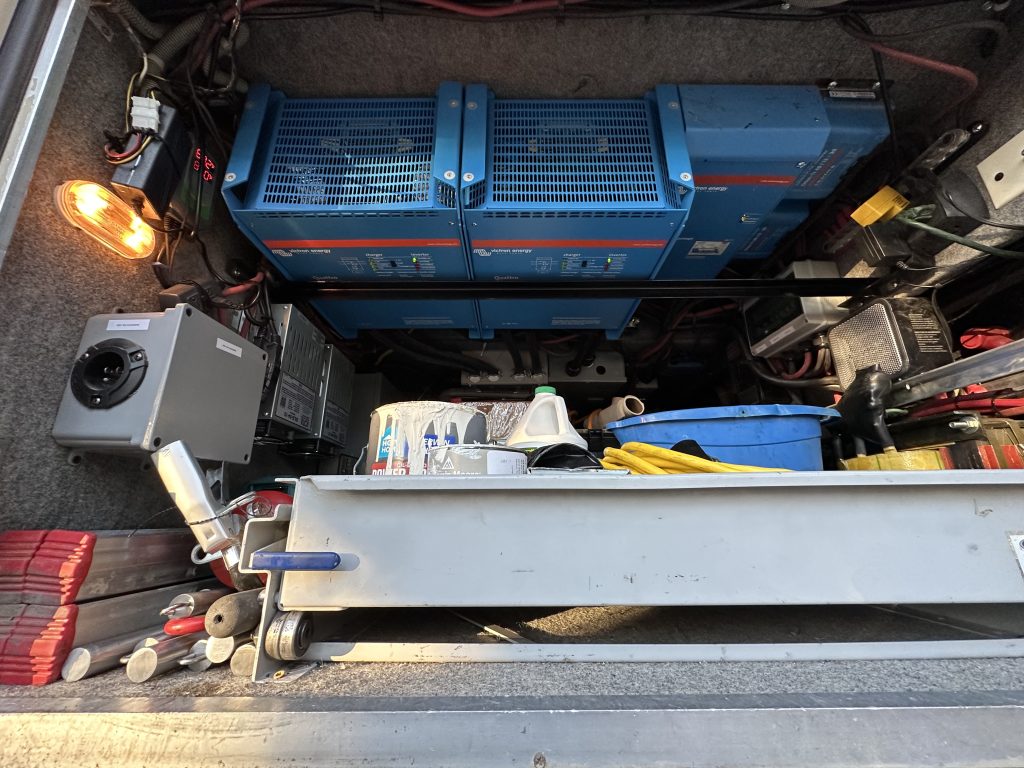

We chose Victron for most components, for their high quality and proven track record in RV applications, as well as their VRM integration and compatibility with third party monitoring components. We’ve installed systems for quite a few systems for other people – from Victron and other vendors – and have found the fewest overall problems with Victron. A non-exhaustive component list is as follows:

- Victron Cerbo GX w/ Touch GX 50

- Victron BMV-712 battery monitor

- GlobalSat BU-353-S4 GPS receiver

- Onan QD8000 w/ Atkinson GSCM-mini

- Custom 8kW 100% duty transformer (step up generator output to 240V)

- 12x REC N-Peak 2 365W panels (4380W)

- 4x Victron SmartSolar 150/35 charge controllers

- 10x SimpliPhi 3.8kWh 48V batteries (38kWh)

- 2x Victron Orion 48/12-30 isolated DC-DC converters

- Dakota Lithium DL+ 60AH 1000CCA 12V battery (720Wh)

- 2x Victron Quattro 48/5000 inverters

- Victron 100A Autotransformer (load balance 120V L1+L2)

- 2x IOTA DLS-54-13 120V 13A chargers on Shellys (120V 15A charging)

- 2x Victron Lynx bus bars, and a few generic bus bars

- Midnite/Outback DC breakers

- Square D QO AC sub panels and breakers

We built a custom rack 11.5″ (on center) off the roof, out of aluminum angle. There are base rails that run the entire length of the roof, that consist of 1-1/2″ angle and are glued down with Sika 291, and anchored through the fiberglass and luan underlay every foot with #14 stainless screws, and through the steel trusses roughly every three feet where they are reachable. All other angle on the roof is 1-1/4″, and everything is 1/8″ wall. The initial height was set to hover just off the low profile factory air conditioning units that were installed on the coach. Panels are bolted down with four or more 1/4″ stainless bolts, and TEK screws at the sides/ends where additional wind load might try to lift them.

Uprights are placed every 16″ for aesthetics purposes, and each upright is held in place by two bolts. Removing an upright allows for someone relatively thin to snake under the panels and work if necessary, without pulling the panels above. I fit in there and have done a relatively large amount of work that way.

All of the wiring from the roof snakes down behind the refrigerator, down to the basement, and along the basement walls to the electrical passthrough bay. As we need as much storage space as possible, all things are mounted to the ceiling and walls according to their size, in order to provide the most usable storage. Batteries are stacked and tucked into otherwise unusable and/or difficult to access dead space forward of the passthrough.

The two 5kVA inverters are stacked, to provide split phase 240V AC output. The neutral from the inverters is not used, but rather 240V AC is fed to an Autotransformer, which provides a neutral and a neutral/ground bond if needed, effectively load balancing L1 and L2 across both inverters. We have a 48V DC native battery bank, and a pair of 30A DC converters providing 12V, and floating a 12V 60AH LiFePO4 battery with a high discharge BMS, that is used when the 60A converter capacity doesn’t suffice.

The generator only provides 120V output, but the inverters require split phase 240V input to run both chargers. A custom transformer was built by EPD that steps it up to 240V with a center tap for split phase. We usually see charge rates from 6.2-6.7kW off the generator, while servicing loads, allowing us to fill up our battery bank from empty (we never let it get anywhere near that low) in 5-6 hours.

The electrical bay is usually passively cooled by a pair of 120mm fans that exhaust the hot air, and heated by proximity to the diesel heating loop. On the rare occasion that we’re in high (95F+) or low (20F-) temperatures, we’ll turn on a 9kW wall unit in the basement to actively cool or heat the bay.

When camping with 30A or 50A service, we will use the standard shore power cord which goes through the inverter. If power is untrustworthy, or less than 30A such as when moochdocking, we will use a pair of IOTA chargers that will max out a 15A circuit and a standalone extension cord. Both IOTA chargers are on Shelly relays, that are tied into Home Assistant, which will enable and disable them as needed based on battery SoC.

Without service, we can generally meet all of our power needs in 30-90F weather without the need to use supplementary power, while running the air conditioners and/or heaters on thermostat to maintain our preferred temps – usually around 70-72F during the day, and 60F at night. Outside of those ranges, we may need to add some generator time. As we generally try to travel with the weather, we keep generator time to a minimum.